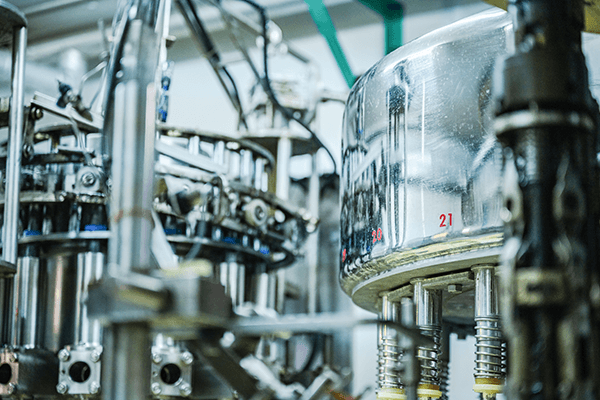

Manufacturers face crucial decisions in the rapidly evolving food industry when producing their products. One of the most significant choices is whether to opt for co-manufacturing or self-manufacturing. Co-manufacturing involves partnering with a specialized facility to produce your food products while self-manufacturing entails setting up and operating your own manufacturing facility. Both approaches have advantages and disadvantages; understanding them is vital for making an informed decision. This blog post will explore the pros and cons of co-manufacture and self-manufacture for food product manufacturers.

Co-Manufacture

Co-manufacturing has recently gained popularity as a strategic solution for food manufacturers. Here are some of the benefits associated with co-manufacturing:

- Cost Savings: Co-manufacturing allows companies to leverage a specialized facility’s expertise, infrastructure, and resources without incurring substantial upfront costs. Manufacturers can allocate their financial resources toward other critical areas such as marketing, research, and development by avoiding significant capital investments.

- Scalability: Partnering with a co-manufacturer provides flexibility in scaling production. Manufacturers can quickly respond to market demands by increasing or decreasing production volumes as needed without being limited by the capacity of their own facilities. This scalability is especially advantageous for seasonal products or when dealing with uncertain market trends.

- Access to Expertise: Co-manufacturing facilities are often equipped with experienced personnel with specialized knowledge in food manufacturing processes, quality control, and regulatory compliance. By tapping into this expertise, manufacturers can benefit from best practices, innovation, and industry insights, enhancing the overall quality of their products.

- Risk Mitigation: Sharing the production responsibility with a co-manufacturer helps mitigate risks associated with equipment failure, labour shortages, and other operational challenges. Additionally, co-manufacturers may have established relationships with suppliers, which can help streamline the supply chain and reduce procurement-related risks.

Read more: Restaurant Technologies that Improve Business

Despite these advantages, co-manufacturing does have some potential drawbacks that manufacturers should consider:

- Loss of Control: Partnering with a co-manufacturer means relinquishing some degree of control over the production process. Manufacturers may have limited influence over production schedules, ingredient sourcing, and quality control protocols. This loss of control can be a concern for companies with unique or highly specialized product requirements.

- Intellectual Property Concerns: Sharing proprietary recipes, formulations, and manufacturing techniques with a co-manufacturer raises intellectual property concerns. While non-disclosure agreements can help protect sensitive information, there is always a risk of intellectual property theft or unintentional disclosure.

Read more: The Truth about Diabetes

Self-Manufacture

Self-manufacturing involves building and operating your own production facility. Here are some advantages associated with self-manufacturing:

- Complete Control: Self-manufacturing gives manufacturers full control over the production process, including ingredient sourcing, quality control, and customization. This level of control can be especially important for companies with unique or proprietary products.

- Brand Identity: By self-manufacturing, companies can establish a stronger brand identity, emphasizing their commitment to quality, authenticity, and innovation. Controlling the entire production process enables manufacturers to align their products closely with their brand values and deliver a consistent customer experience.

- Flexibility and Adaptability: Having an in-house manufacturing facility offers the flexibility to adapt quickly to changing market dynamics, consumer preferences, and emerging trends. Manufacturers can experiment with new recipes, variations, and packaging formats more easily, enabling them to stay competitive.

However, self-manufacturing also presents some challenges that manufacturers should be aware of:

- Higher Costs: Setting up and operating a manufacturing facility requires substantial infrastructure, equipment, and skilled labour investments. Manufacturers must consider the financial implications of these upfront costs, including maintenance, compliance, and ongoing operational expenses.

- Limited Scalability: Self-manufacturing restricts scalability compared to co-manufacturing. Expanding production capacity might require significant investments, and manufacturers may face challenges adjusting output to match fluctuating demand.

Co-manufacture and self-manufacture are two viable options for food manufacturers, each with advantages and challenges. When deciding, it is crucial to consider factors such as cost, control, scalability, expertise, and brand identity. Ultimately, the choice depends on the individual manufacturer’s specific needs, goals, and resources. By weighing these considerations thoughtfully, manufacturers can make an informed decision that aligns with their business objectives and helps drive growth and success in the competitive food industry.

Read more: Food Labeling Modernization Act: Why it Matters for Food Manufacturers

Nutrition Analysis with MenuSano

In addition to considering the co-manufacture vs. self-manufacture decision, food manufacturers can leverage technology to streamline their operations and enhance their business. One such tool that can significantly benefit food manufacturers is MenuSano, a user-friendly nutrition analysis software. MenuSano offers a range of features that can help manufacturers in several ways.

Firstly, MenuSano allows manufacturers to easily analyze and calculate the nutritional information of their recipes and food products. With its extensive database of ingredients, manufacturers can input their recipes and obtain accurate and detailed nutritional breakdowns, including calories, macronutrients, vitamins, and allergen information. This functionality is crucial for complying with labelling regulations, meeting consumer demand for transparency, and catering to specific dietary requirements.

Moreover, MenuSano enables manufacturers to create and compare multiple recipe versions, allowing them to experiment with ingredient substitutions or modifications while instantly assessing the impact on nutrition profiles. This feature helps manufacturers optimize their recipes to meet specific nutritional targets or align with market trends without compromising taste or quality.

Lastly, MenuSano’s user-friendly interface and intuitive design make it accessible to all users, even those without extensive technical expertise. This ease of use reduces the learning curve for employees and allows manufacturers to integrate the software into their operations efficiently.

By leveraging MenuSano, food manufacturers can streamline their nutritional analysis processes, ensure regulatory compliance, optimize recipes, control costs, and provide consumers with accurate and transparent product information. Incorporating technology tools like MenuSano into their operations can help food manufacturers stay competitive, meet consumer expectations, and drive growth in the dynamic and evolving food industry.

If you want to see just how much MenuSano can help, you can sign up for a Free Trial today!